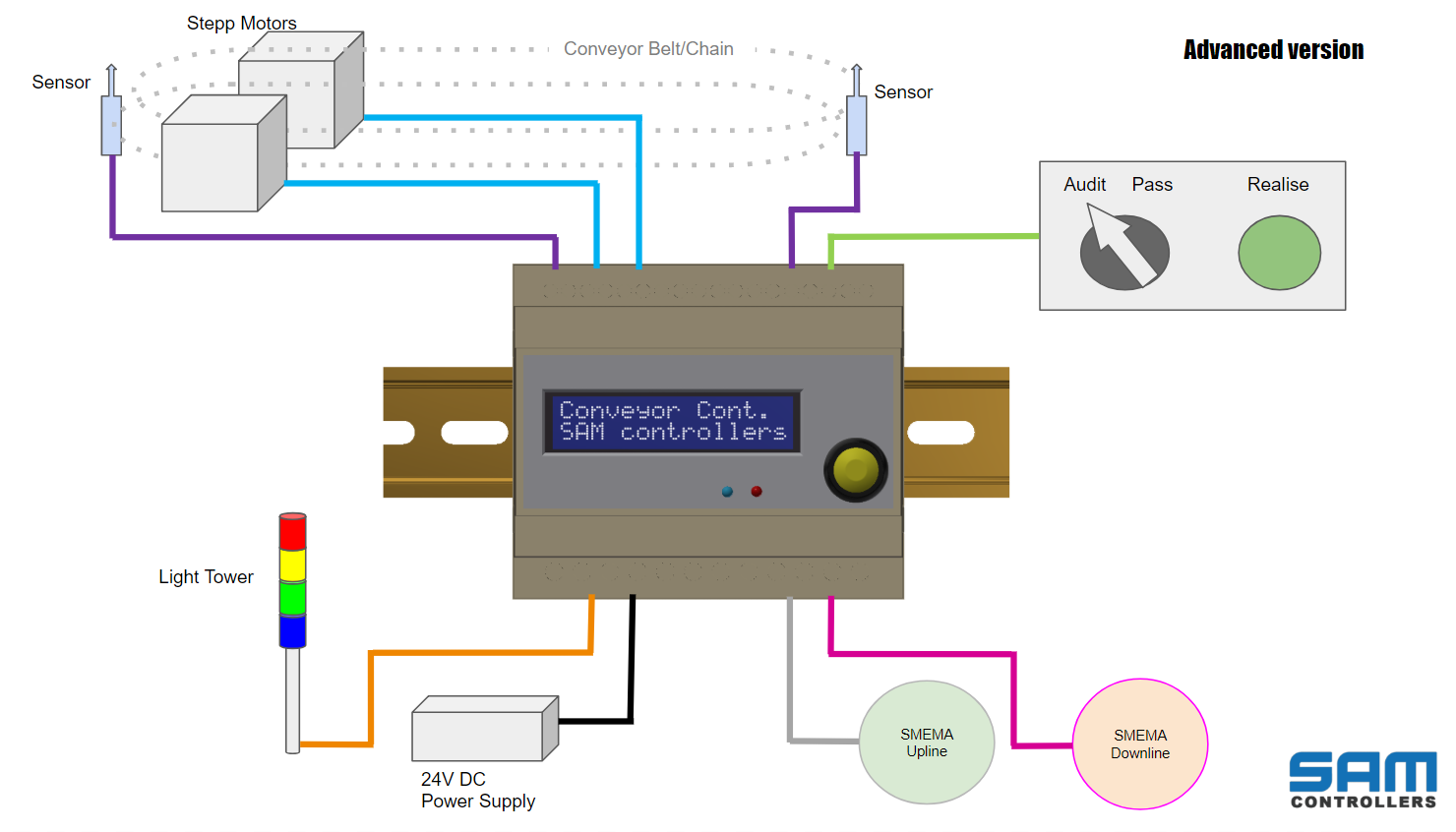

The State-of-the-Art flexible Conveyor Controller is designed to completely replace the standard PLC controller and any associated type of speed controllers. A natural Task Oriented Optimal Computing (TOOC) based system provides flexibility to build or repair virtually any conveyor setup with a “one stop” conveyor setup.

Adjustable speed with Fast/Slow modes operates in Left-to-Right or Right-to-Left setup scenarios. The advanced version has a built-in LCD screen that displays information on processing boards and explanations of triggered alarms. Multiple stop controllers are avaliable as a custom order.