Compressor unloader valve releases the pressure from the pump motor before and after compression. You will know the unloader valve by its instinctive sound after the compressor has reached its high setpoint.

How the unloader valve works

Compressor Start: Before an air compressor starts the pump must be unloaded as starting the compressor with pressure in the pump is much like starting a car that is in gear.

Compressor Stop: After a compressor stops the compressed air remaining in the pump overhead is released into the atmosphere through the unloader valve.

Typically unloader valves are configured to be normally open (when no energy is applied to the valve it remains open)

Locating the Unloader Valve:

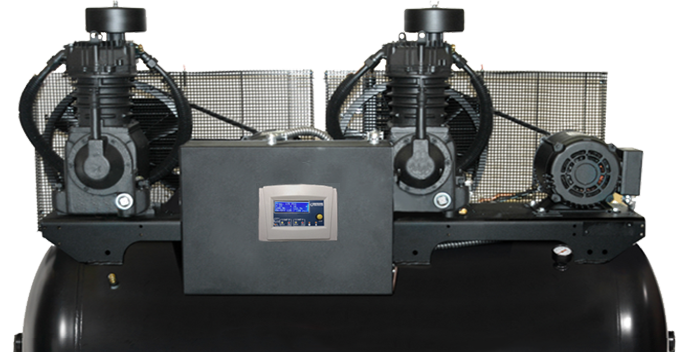

The unloader valve is located somewhere in the line between the compressor and the compressor tank. There are many differences in the types of unloader valves and they vary greatly between compressor manufacturers. Typically there are two main types of valves: Mechanical and Electrical.

It is often part of the pressure switch assembly. It will, in many cases, be opened by the pressure switch as the switch operates, or it could be built as a centrifugal switch on the Pump axes.

When the air in the compressor air tank reaches the cut out set point and the pressure switch switches off the power to the compressor’s electric motor, that movement toggles the unloader valve to open and relief the air pressure in the pump overhead.

The purpose of the unloader valve, regardless of its shape or location on the compressor or if it is mechanically / electrically operated, is to unload the air trapped within the air compressor pump before and after the compressor runs.

How Compressor Controller manages the unloader valve

The Compressor Controller Model R intelligently actuates the air compressor unloader valve to maximize air compressor efficiency, quality and longevity.

Compressor Start: When the compressor starts the unloader valve is opened until the compressor pump is warmed up to perform optimally (Typically taking less than 10 seconds). The unloader valve is then closed and the air compressor begins compressing air.

This method of unloader valve control is proprietary to the Compressor Controller Model R and provides the following benefits:

- Lowers the peak current when starting compressors

- Reduces oil-water contamination in the pump

- Lowers the amount of condensate that enters the storage tank

- Increases the life of the compressor

Compressor Stop: After the compressor reaches the cut out set point, the motor is shut off and the unloader valve is opened, draining and unloading the pump.

Unloader valve selection to use with the Compressor Controller

There are various types of electrically operated valves used in industries. For the installation with Compressor Controller we suggest to install a solenoid type valve with the same voltage as you compressor.

If your compressor has an electrically operated unloader valve it is possible to connect it to the Compressor Controller. Make certain that the power and pressure requirements are compatible.

If your air compressor has an integrated mechanical unloader valve it is not necessary to remove it, it can be left in place and an electronically operated valve can be added.

Unloader Valve Plug

The plug that is installed into the drain valve should have an orifice sized so the pressure release / air purge after the compressor has run should take about 5 seconds.

Installation Example

5HP Single Phase Air Compressor

80 Gallon receiver tank

120 PSI operating pressure

Unloader Valve: 110VAC NO (Normally Open) 1/8 NPT electric solenoid (Grainger Item # 39P476)

Unloader Valve Plug: (Grainger Item # 6AYZ7 ) and a 1/16″ orifice drilled out (to satisfy a 5 second air purge)