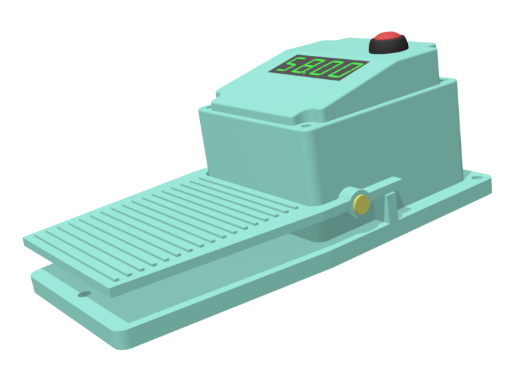

PWM DC Motor Pedal Controller provides reliable and repeatable control for any DC load to up to 35A.

A basic version with simple multicolor LED will inform you on general status of the controller, and Buzzer will provide additional audible confirmation on process starts and alarms.

With optional 4 digit, 7 segment display could be build any type of winding or conveying mechanism, where need to count events, and input could be from any dry relay or NPN transistor.

As an advanced display option, we offer build-in 16 char x2 lines display with wide selection of information screen to show usage and performance parameters.

As a next step to upgrade, a remote 20 char x 4 lines display would be offered.