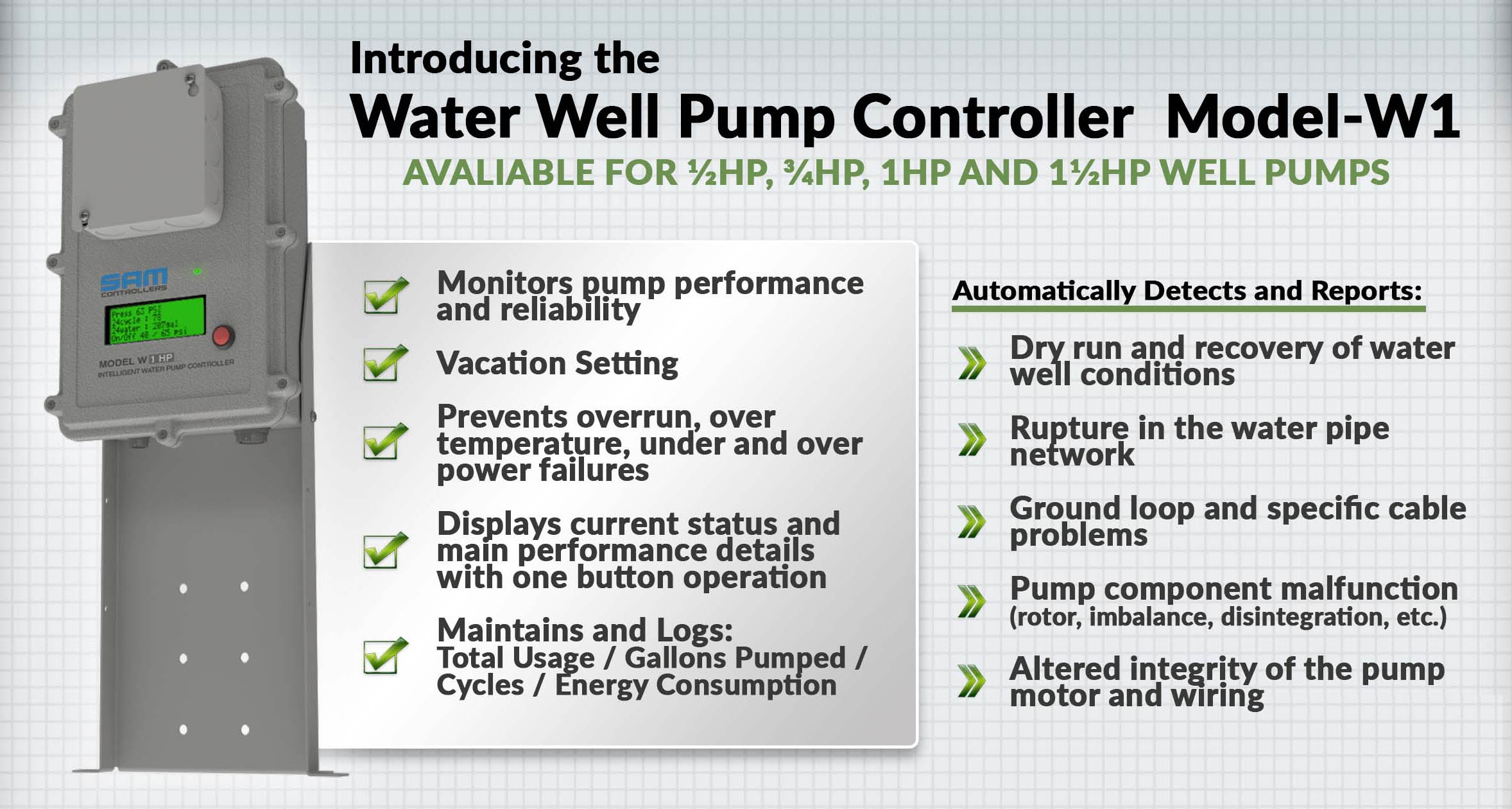

The physics behind water well pumps is universal and the SAM Controller provides control, data and analytics for all of them. No matter the pump application, the SAM Pump Controller will improve the performance, reduce the operating costs, extend the life of the water and sewage pumps.

The SAM Well Pump Controller is flexible with multiple inputs and outputs to satisfy almost any configuration with highly valuable applications.